Transforming Business with Rapid Prototyping 3D Printing

In the modern landscape of manufacturing and design, rapid prototyping 3D printing has emerged as a revolutionary technology. It has changed the way businesses approach product development, allowing for faster, more efficient processes. This article delves into the significant advantages of rapid prototyping 3D printing, explaining how it can not only enhance production efficiency but also foster innovation and creativity within organizations.

Understanding Rapid Prototyping 3D Printing

Rapid prototyping refers to the quick fabrication of a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. This process allows for the quick iteration of product designs, facilitating early detection of design flaws and enabling modifications before full-scale production.

At its core, 3D printing (or additive manufacturing) creates objects layer by layer from digital models. This technology not only reduces the time from concept to product but also significantly decreases material waste compared to traditional manufacturing methods.

The Benefits of Rapid Prototyping 3D Printing for Businesses

Rapid prototyping 3D printing offers numerous benefits that can significantly improve business operations:

- Speed: Traditional prototyping methods can take weeks or even months. In contrast, 3D printing can produce a prototype in a matter of hours.

- Cost Efficiency: By minimizing material waste and reducing labor costs, businesses can see substantial cost savings.

- Enhanced Collaboration: Sharing high-quality prototypes among team members can enhance collaboration and feedback.

- Customization: 3D printing allows for high levels of customization without the need for extensive additional costs.

- Reduced Risk: Early prototyping allows businesses to better understand market needs and avoid costly production errors.

Applications of Rapid Prototyping 3D Printing

The applications of rapid prototyping 3D printing are vast and varied across different industries:

1. Product Development

In product development, companies can utilize 3D printing to create prototypes of consumer goods, testing ergonomics and design before investing in mass production.

2. Automotive Industry

The automotive sector uses rapid prototyping 3D printing for prototype parts and tools, significantly speeding up the design and testing phases.

3. Aerospace

Aerospace industries frequently rely on rapid prototyping for complex parts that require strict safety standards, making iterative testing crucial.

4. Healthcare

In healthcare, 3D printing has been used for creating customized implants, prosthetics, and even organ models for surgical preparation.

5. Consumer Products

From toys to electronics, consumer product firms are leveraging 3D printing to bring innovative ideas to market faster than ever before.

The 3D Printing Process: A Closer Look

Understanding the process of rapid prototyping 3D printing is essential for businesses looking to implement this technology:

1. Design Creation

The journey begins with a design, created using CAD software. Ensuring that the design is optimized for 3D printing is crucial for achieving the best results.

2. Slicing the Model

The CAD model is then sliced into thin horizontal layers using slicing software, which converts the design into machine instructions.

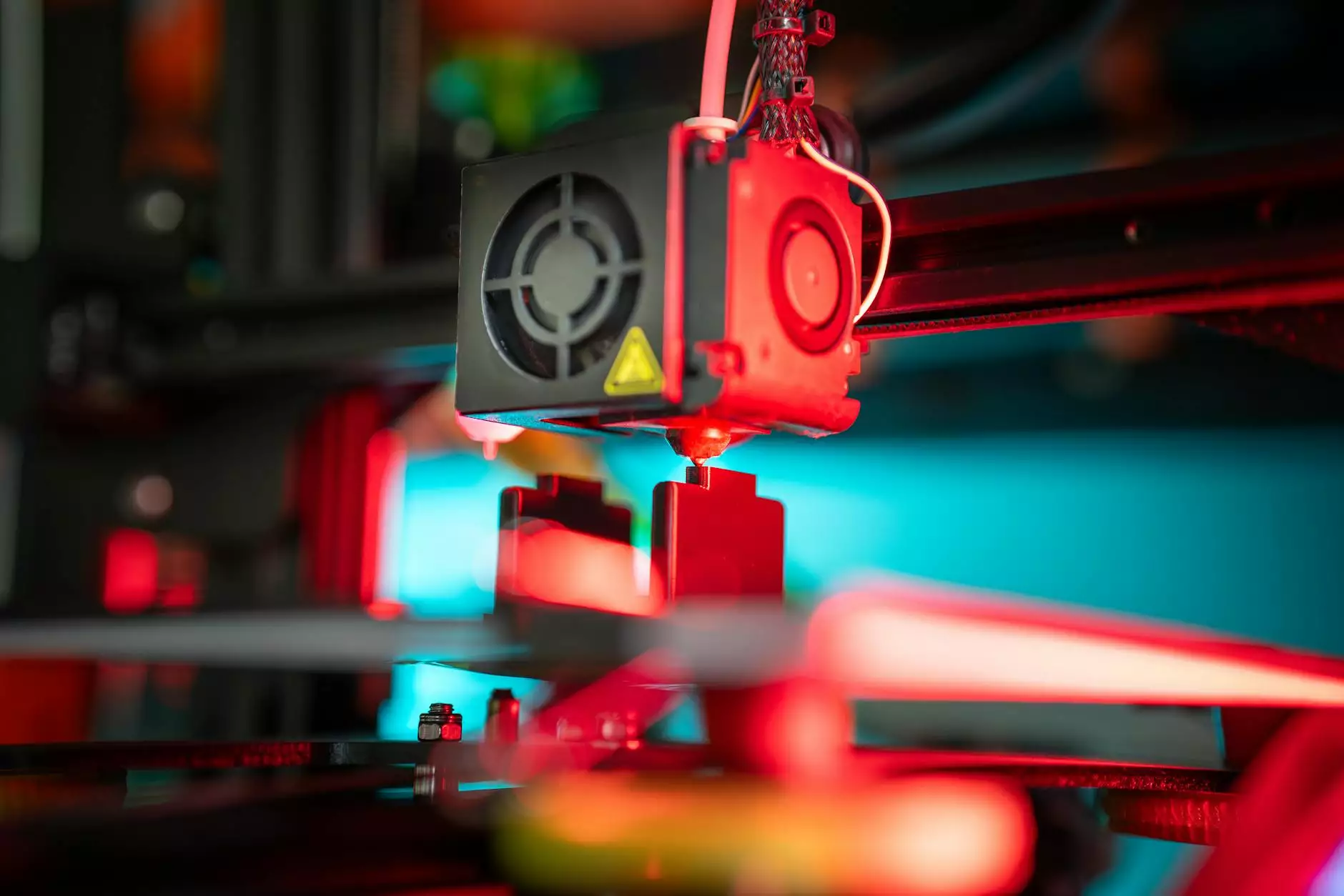

3. Printing the Prototype

The 3D printer reads the sliced model and begins constructing the prototype layer by layer, utilizing various materials such as plastics, metals, or composites.

4. Post-Processing

Once printing is complete, the prototype may require post-processing, such as cleaning, smoothing, or finishing, to enhance its appearance and functionality.

Choosing the Right 3D Printing Technology

There are several types of 3D printing technologies to choose from, each with its unique benefits:

- Fused Deposition Modeling (FDM): Ideal for prototyping with thermoplastic materials.

- Stereolithography (SLA): Provides high precision and smooth finishes for intricate designs.

- Selective Laser Sintering (SLS): Suitable for functional parts and low-volume production runs.

- Digital Light Processing (DLP): Similar to SLA but uses a digital light projector for rapid layer curing.

- Metal 3D Printing: Emerging as a strong contender for producing complex metal components effectively.

Challenges in Rapid Prototyping 3D Printing

While the advantages of rapid prototyping 3D printing are compelling, businesses should also be aware of the challenges:

- Initial Investment: High-quality 3D printers and materials can be expensive, representing a significant upfront cost.

- Material Limitations: Not all materials are currently available for 3D printing, which may limit design options.

- Technical Expertise: Companies may need to invest in training personnel to effectively use 3D printing technology.

- Intellectual Property Risks: The ease of replicating designs can pose risks to intellectual property, necessitating thorough protective measures.

Future Trends in Rapid Prototyping 3D Printing

The future of rapid prototyping 3D printing looks promising, with continuous advancements expected:

1. Expandable Material Options

As research progresses, expect a broader range of materials, including advanced composites and bio-materials, opening up new opportunities for businesses.

2. Increased Automation

Automation in 3D printing processes can streamline production, making it accessible for small to medium enterprises.

3. Integration with AI

Using Artificial Intelligence for optimizing designs and analyzing printing processes can significantly enhance the efficiency and quality of outcomes.

Conclusion: Embracing Rapid Prototyping 3D Printing for Business Growth

In an era where innovation drives success, rapid prototyping 3D printing stands as a pivotal tool for businesses, enabling them to stay competitive in the market. By embracing this technology, companies can accelerate their product development processes, reduce costs, and foster an environment of creativity and innovation.

To succeed in today’s fast-paced environment, organizations must adapt to cutting-edge technologies like rapid prototyping 3D printing. As exemplified by industry leaders, leveraging this technology is not just an option but a necessity for future growth and sustainability.

For more information on how you can implement rapid prototyping 3D printing in your business, visit deepmould.net today.