Medical Devices Factories: Innovating Radiation Shielding Solutions

In today’s modern healthcare environment, medical devices factories play a critical role in developing sophisticated health solutions that prioritize patient safety and effective treatment. Among the various innovations emerging from these factories, radiation shielding materials and radiation shielding devices have gained significant attention. This article delves into the significance of medical device manufacturing, the various types of radiation shielding materials, advancements in technologies, and a spotlight on OVM Device, a leading provider in the industry.

The Importance of Medical Devices Factories

Medical devices factories are at the forefront of technological innovation and healthcare solutions. These facilities are where raw materials are transformed into functional medical products that are essential to diagnostics, treatment, and patient care.

In the realm of radiation protection, these factories are pivotal for producing components that protect both healthcare workers and patients from harmful radiation exposure. The ongoing advancements in medical technology demand that these factories remain compliant with safety regulations while continuously innovating to meet the evolving needs of healthcare providers and patients alike.

Understanding Radiation Shielding Materials

Radiation shielding materials are essential in mitigating exposure to various types of radiation, which can be harmful or even lethal if unchecked. There are several types of radiation—such as ionizing radiation from X-rays and gamma rays—that necessitate specialized shielding techniques.

Types of Radiation Shielding Materials

Several materials are commonly utilized in the production of radiation shielding:

- Lead: One of the most well-known shielding materials, lead is dense and effective against gamma and X-ray radiation.

- Concrete: A cost-effective alternative often used in constructing shielding walls, providing substantial absorption for low energy radiation.

- Boron: Effective against neutron radiation, boron is often mixed with polyethylene or used in specialized formulations.

- Plastic and Polyethylene: These materials can be infused with different additives to create lightweight and effective radiation shielding solutions, making them versatile for various applications.

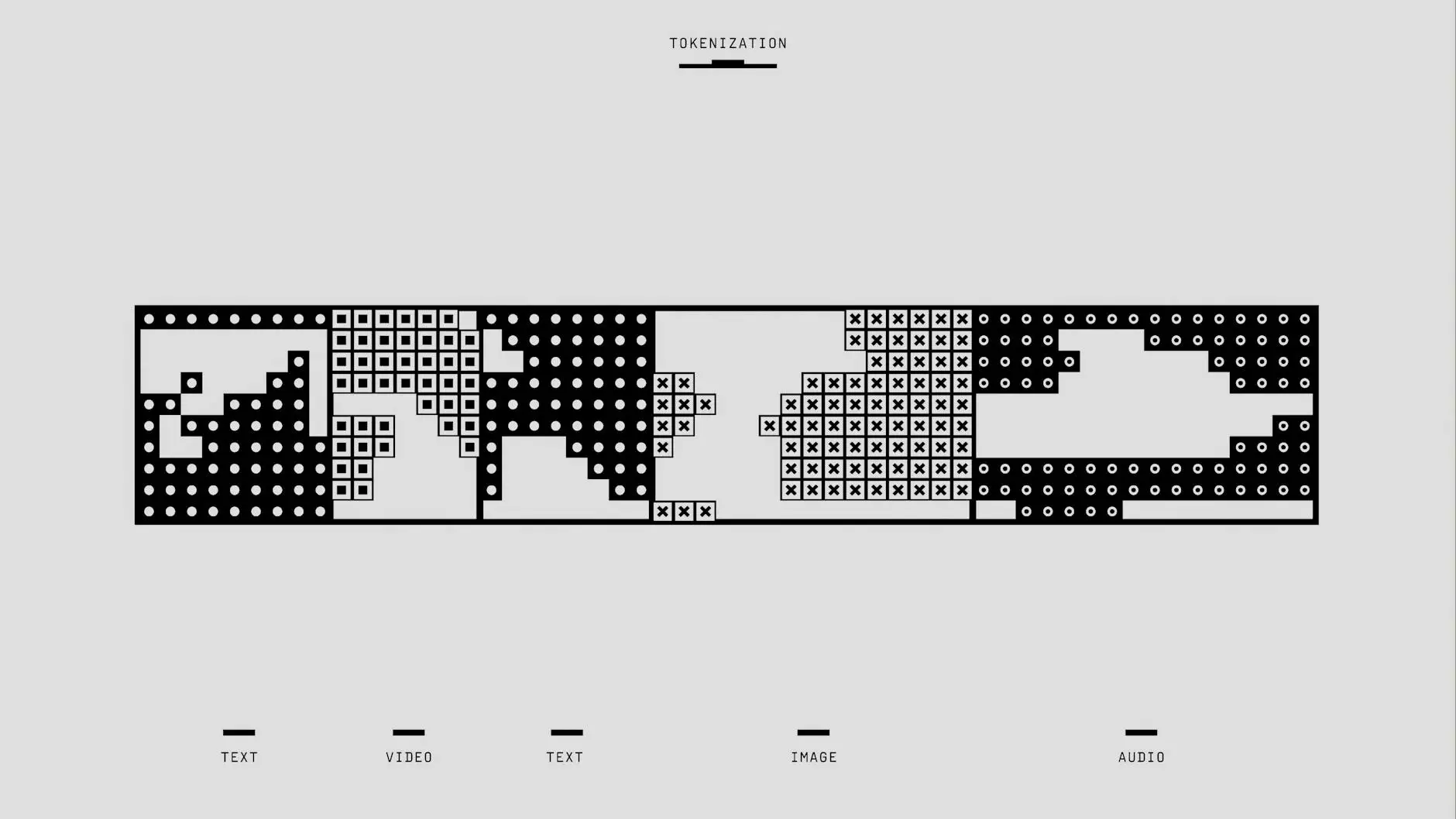

Innovations in Radiation Shielding Devices

As the healthcare industry evolves, so do the technologies behind radiation shielding devices. These innovations help ensure maximum protection using the least amount of material and minimizing weight burdens for ease of use.

Recent Advancements

Some notable advancements include:

- Smart Shielding Materials: Incorporating technology that allows for dynamic responses to radiation levels, adjusting shielding properties in real-time.

- 3D Printing Technology: This enables the production of intricate designs that optimize material use while ensuring maximum protection based on specific usage scenarios.

- Enhanced Fabrication Techniques: New methods to improve the bonding and layering of different materials for superior composite shields.

OVM Device: A Leader in Medical Device Factory Innovations

OVM Device has established itself as a leader amongst medical devices factories specializing in radiation shielding devices and materials. With a commitment to quality and innovation, OVM Device utilizes cutting-edge technology to ensure that all products meet the highest safety standards.

Quality Assurance Measures

At OVM Device, quality assurance is paramount. Rigorous testing and compliance checks are conducted on all products to ensure they meet both national and international radiological safety standards. This attention to detail solidifies their reputation in a competitive landscape.

Commitment to Sustainability

The future of medical device manufacturing lies in sustainable practices. OVM Device is actively investing in eco-friendly materials and manufacturing processes that reduce environmental impact while maintaining product efficacy and safety.

Future Directions in Medical Device Manufacturing

The future of medical devices factories and radiation shielding technologies is bright. New regulations demanding higher safety standards alongside the growth of the radiological imaging market ensures continuous demand for innovative solutions.

Emerging Trends

Some key trends to watch include:

- Integration of Artificial Intelligence: AI is being employed to improve design processes and manufacturing efficiency.

- Increased Telehealth Applications: With the rise of telehealth, there is a growing demand for portable radiation shielding solutions.

- Personalized Medicine: Tailoring radiation shielding solutions based on patient demographics and specific treatment requirements.

Conclusion

In summary, medical devices factories like OVM Device are crucial players in the continuous advancement of healthcare technologies. As the industry evolves, the focus on high-quality radiation shielding materials and radiation shielding devices will grow in importance. The commitment to innovative practices, sustainability, and compliance with safety regulations will position these factories at the heart of the healthcare revolution, ultimately leading to better patient outcomes and improved safety standards across the medical landscape.

Investing in innovations developed by facilities such as OVM Device ensures not only the safety of healthcare workers and patients but also contributes to more effective treatment modalities that harness the power of radiation safely and effectively.