Silica sand vs Green sand - Understanding the Differences

Artificial Grass

Welcome to Metate Industrial Supply's in-depth analysis of silica sand versus green sand. In this article, we will explore the characteristics, applications, benefits, and drawbacks of both types of sand, aiding you in making informed decisions for your specific industrial needs.

1. What is Silica Sand?

Silica sand is a naturally occurring granular material composed of finely divided rock and mineral particles. It is primarily composed of silica, a compound made up of silicon and oxygen. Silica sand is known for its high purity and is commonly used in industrial processes due to its desirable physical and chemical properties.

2. Properties and Applications of Silica Sand

Due to its excellent thermal stability, high melting point, and low thermal expansion, silica sand finds widespread applications in various industries:

- Glass Manufacturing: Silica sand is an essential ingredient in glass production, providing transparency, strength, and durability to the final product.

- Metal Casting: Foundry-grade silica sand is extensively used in metal casting processes to produce molds and cores for intricate metal components.

- Construction Material: Silica sand is utilized in construction as a primary component in concrete, mortar, and other building materials.

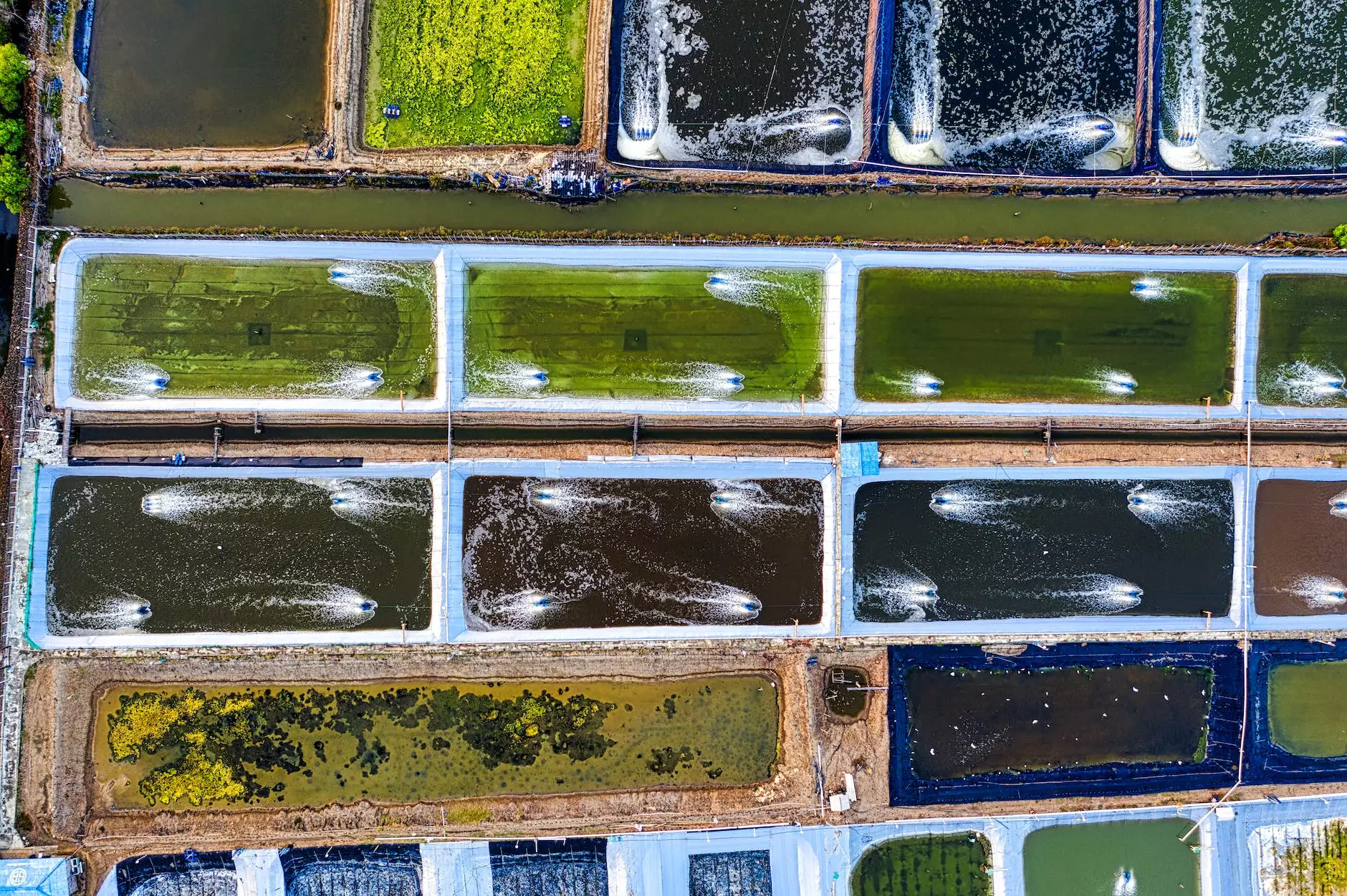

- Water Filtration: Due to its excellent filtration properties, silica sand is commonly used in swimming pool filters, wastewater treatment plants, and drinking water purification systems.

- Sports Field Infill: Silica sand is used as an infill material in artificial sports fields, enhancing playability and reducing the risk of player injuries.

3. What is Green Sand?

Green sand, also known as molding sand, is a mixture of silica sand, bentonite clay, water, and other additives. It gets its name from the fact that the sand mixture appears green due to the presence of moisture and organic compounds.

4. Characteristics and Applications of Green Sand

Green sand, with its unique properties, is widely employed in various industries:

- Foundries: Green sand is extensively used in foundries as a molding material, facilitating the production of intricate metal parts with excellent surface finish and dimensional accuracy.

- Automotive Applications: The automotive industry utilizes green sand molds to produce engine blocks, cylinder heads, and other metal components.

- Art and Jewelry Casting: Green sand is commonly employed in the creation of artistic and jewelry pieces through the process of sand casting.

- Other Industrial Applications: Green sand can also be used in various industrial applications such as producing clay bricks and ceramics.

5. Comparison - Silica Sand vs Green Sand

Now that we have explored the individual properties and applications of silica sand and green sand, let's compare them side by side:

5.1 Physical Properties

Silica Sand: Silica sand offers excellent thermal stability, high melting point (above 1,700°C), low thermal expansion, and exceptional hardness.

Green Sand: Green sand possesses good mold strength, high permeability, and enables complex casting designs.

5.2 Chemical Composition

Silica Sand: Silica sand is primarily composed of silicon dioxide (SiO2), with traces of other minerals and impurities.

Green Sand: Apart from silica, green sand consists of bentonite clay and water, with additional additives depending on the specific requirements.

5.3 Applications

Silica Sand: Silica sand finds extensive applications in glass manufacturing, metal casting, construction, water filtration, and sports field infill.

Green Sand: Green sand is predominantly used in foundries, automotive applications, art and jewelry casting, and other industrial processes.

5.4 Environmental Considerations

Silica Sand: Silica sand is generally considered safe for the environment, but prolonged inhalation can pose health risks.

Green Sand: Green sand, when properly managed, is a relatively safe and sustainable material for casting applications.

6. Conclusion

In conclusion, both silica sand and green sand offer distinct advantages and have their specific applications within various industries. Understanding the differences between these two types of sands is crucial in identifying the most suitable sand for your industrial requirements.

At Metate Industrial Supply, we provide a wide range of high-quality silica sand and green sand products, backed by our expertise and commitment to customer satisfaction. Contact us today to discuss your sand requirements and let our knowledgeable team assist you in making the right choice!